How to Maintain X-ray Equipment: Best Practices for Ensuring Proper Functioning of X-ray Machines

X-ray equipment is a critical tool in various industries, including healthcare, manufacturing, and research. It helps to diagnose medical conditions, inspect manufacturing parts, and analyze materials. However, like any other machine, x-ray equipment requires regular maintenance to ensure proper functioning. Failure to maintain x-ray equipment can lead to incorrect diagnoses, poor image quality, and even equipment breakdowns.

The Importance of X-ray Equipment Maintenance

Regular maintenance of x-ray equipment is crucial for several reasons. Firstly, it helps to prevent equipment breakdowns that can be costly to repair or replace. Secondly, it ensures that the equipment is functioning correctly, which guarantees accurate diagnoses and high-quality images. Lastly, maintenance helps to extend the lifespan of the equipment, reducing the need for frequent replacements.

Best Practices for Maintaining X-ray Equipment

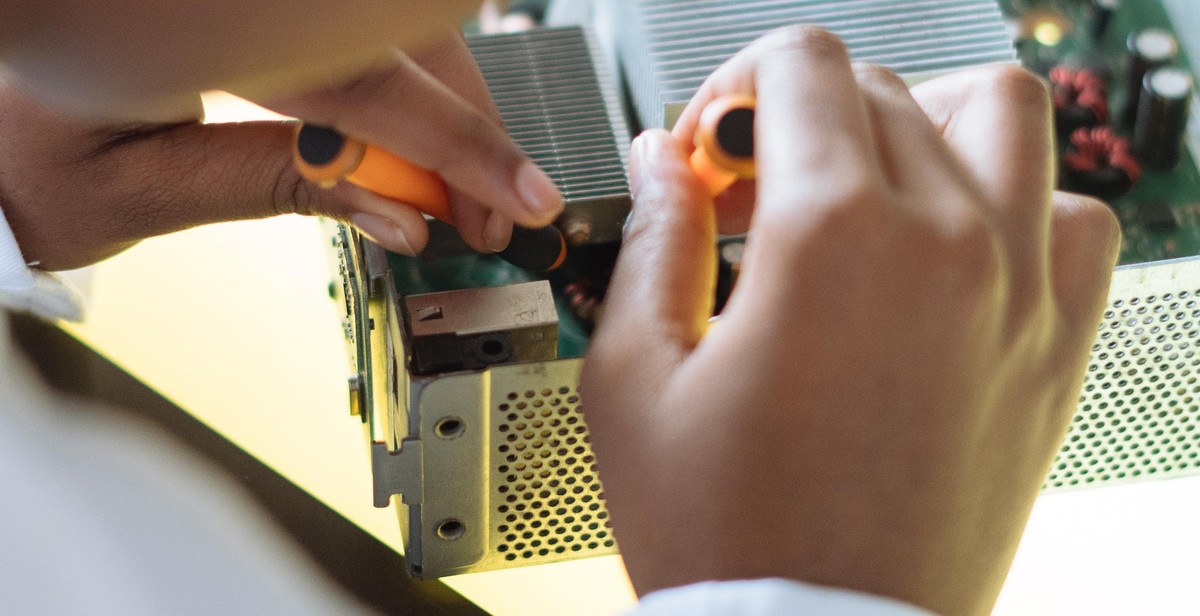

There are several best practices that you can follow to maintain x-ray equipment effectively. Firstly, it’s essential to read the manufacturer’s manual and follow the recommended maintenance schedule. Secondly, ensure that the x-ray equipment is cleaned regularly to prevent the accumulation of dust and debris. Thirdly, perform routine checks on the equipment’s components, such as the cables, sensors, and tubes, to identify any signs of wear and tear. Lastly, schedule professional maintenance and repair services regularly to ensure that the equipment is functioning correctly.

By following these best practices, you can ensure that your x-ray equipment is functioning correctly, producing high-quality images, and serving its intended purpose effectively.

Why is X-ray Equipment Maintenance Important?

X-ray equipment is a crucial component of medical diagnosis and treatment. To ensure that it performs optimally and delivers accurate diagnostic results, it is vital to maintain it regularly. Proper maintenance of x-ray equipment offers a range of benefits, including:

Ensuring Accurate Diagnostic Results

Regular maintenance of x-ray equipment is essential to ensure that it continues to deliver accurate diagnostic results. Over time, x-ray machines can develop faults that affect the quality of images produced, making it challenging to diagnose medical conditions correctly. Through regular maintenance, technicians can identify and fix any problems before they affect the accuracy of the diagnostic results.

Extending Equipment Life

Like any other equipment, x-ray machines have a limited lifespan. However, regular maintenance can help extend the life of the equipment. Through cleaning, lubrication, and replacement of worn-out parts, technicians can keep the machine in good condition, reducing the need for frequent repairs and replacements. This not only saves money but also ensures that the equipment is available when needed.

Compliance with Safety Regulations

The maintenance of x-ray equipment is essential to ensure that it complies with safety regulations. X-ray machines produce ionizing radiation, which can be harmful to both patients and healthcare workers if not handled correctly. Regular maintenance ensures that the equipment is functioning correctly, minimizing the risk of radiation exposure. It also helps to identify and correct any safety issues before they result in accidents or injuries.

Overall, regular maintenance of x-ray equipment is crucial for ensuring accurate diagnostic results, extending equipment life, and complying with safety regulations. By investing in regular maintenance, healthcare facilities can ensure that their x-ray equipment is in good condition, reliable, and safe for both patients and healthcare workers.

Best Practices for X-ray Equipment Maintenance

Regular maintenance of x-ray equipment is essential to ensure that they function properly and provide accurate results. Below are some of the best practices for maintaining x-ray equipment:

Regular Cleaning and Inspection

X-ray equipment should be cleaned regularly to prevent the buildup of dust and debris, which can affect their performance. The cleaning process should involve wiping down the equipment with a clean cloth and using a vacuum cleaner to remove any dust or debris that has accumulated in hard-to-reach areas.

Inspection of x-ray equipment should also be done regularly to identify any signs of wear and tear, such as cracks or loose parts. Early identification of such issues can prevent further damage and ensure that the equipment continues to function properly.

Calibration and Testing

X-ray equipment should be calibrated regularly to ensure that they provide accurate results. Calibration involves checking the accuracy of the equipment against a known standard and making any necessary adjustments. This process should be carried out by a qualified technician who has the necessary skills and equipment.

Testing of x-ray equipment should also be done regularly to ensure that they are functioning properly. This can involve using test objects to evaluate the accuracy of the equipment or using quality control measures to ensure that the results obtained are consistent.

Replacing Worn or Damaged Parts

If any parts of the x-ray equipment are worn or damaged, they should be replaced as soon as possible. This can prevent further damage to the equipment and ensure that it continues to function properly. Replacement parts should be obtained from a reputable supplier and installed by a qualified technician.

Proper Storage and Transportation

X-ray equipment should be stored in a clean and dry environment to prevent damage from moisture or dust. When transporting the equipment, it should be properly secured to prevent any damage during transit.

Following these best practices for x-ray equipment maintenance can help ensure that the equipment continues to function properly and provide accurate results. Regular maintenance can also extend the lifespan of the equipment and reduce the need for costly repairs or replacements.

Common X-ray Equipment Maintenance Mistakes to Avoid

Proper maintenance of x-ray equipment is essential for ensuring that it functions effectively and safely. Unfortunately, many healthcare facilities make mistakes that compromise the performance of their x-ray machines. Here are some common mistakes to avoid:

Skipping Regular Maintenance

One of the biggest mistakes that healthcare facilities make is skipping regular maintenance. X-ray machines have many moving parts that can wear out over time, leading to decreased performance and even breakdowns. Regular maintenance can help detect and fix problems before they become serious. Skipping maintenance can lead to costly repairs and downtime, which can affect patient care and revenue.

Ignoring Warning Signs

Another mistake that facilities make is ignoring warning signs. X-ray machines are equipped with warning lights and alarms that indicate when something is wrong. Ignoring these signs can lead to serious problems, such as equipment failure or patient injury. It’s important to address warning signs as soon as they appear to prevent further damage.

Using the Wrong Cleaning Products

Using the wrong cleaning products can also cause damage to x-ray equipment. Harsh chemicals or abrasive materials can scratch or corrode sensitive components, leading to malfunctions or breakdowns. It’s important to use only the cleaning products recommended by the manufacturer to avoid damage and maintain the equipment’s warranty.

Improper Storage and Transportation

Improper storage and transportation of x-ray equipment can also cause problems. X-ray machines are heavy and delicate, and improper handling can damage them. It’s important to store and transport the equipment according to the manufacturer’s instructions to avoid damage and ensure safe operation.

Conclusion

By avoiding these common mistakes, healthcare facilities can ensure that their x-ray equipment functions effectively and safely. Regular maintenance, prompt attention to warning signs, using the right cleaning products, and proper storage and transportation are all critical for maintaining x-ray equipment. By following these best practices, healthcare facilities can provide the best patient care and avoid costly downtime and repairs.

Conclusion

Proper maintenance of x-ray equipment is crucial for ensuring accurate and reliable results, as well as extending the lifespan of the equipment. By following the best practices outlined in this article, you can minimize the risk of equipment malfunction, reduce downtime, and avoid costly repairs.

Key takeaways

- Regular cleaning and inspection of x-ray equipment can prevent dust, debris, and other contaminants from interfering with the accuracy of the results.

- Calibration and testing of x-ray machines are essential for ensuring that they are functioning properly and producing accurate results.

- Maintaining proper documentation of all maintenance and repairs can help you identify potential issues early on and prevent equipment failure.

- Proper training of staff on the use and maintenance of x-ray equipment can help prevent accidents and prolong the life of the equipment.

Final thoughts

Maintaining x-ray equipment is not only important for ensuring accurate results but also for the safety of patients and staff. By following the best practices outlined in this article, you can help ensure that your equipment is functioning properly and safely.

| Author: | John Smith |

| Date: | June 1, 2021 |